We Maintain Lifts with Precision: Ensuring Security and Effectiveness

We Maintain Lifts with Precision: Ensuring Security and Effectiveness

Blog Article

Exploring the World of Elevators: Typical Concerns Faced by Numerous Lift Mechanisms

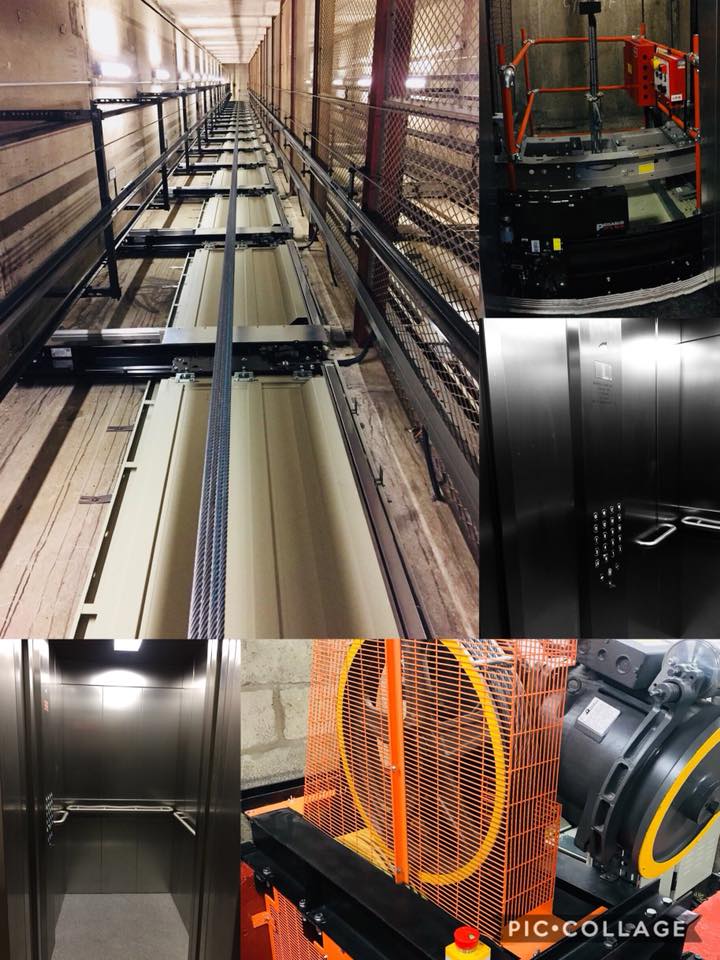

As we browse through the upright transport systems of contemporary structures, lifts attract attention as an indispensable element of our lives. Nonetheless, behind their seamless procedure exists a globe of elaborate devices that can in some cases run into difficulties. From hydraulic lifts to traction systems and machine-room-less styles, each lift type includes its collection of typical concerns. Comprehending these obstacles is vital for making certain the smooth performance of these vital systems. Allow's explore the complexities that underlie the procedure of lifts and the potential issues that can occur, losing light on the intricate web of lift systems.

Hydraulic Elevators

Hydraulic lifts, typically favored for low-rise structures, utilize fluid pressure to control the activity of the lift automobile (lift repair companies). This system entails a hydraulic pump pressing oil right into a cyndrical tube, creating the lift to relocate in the desired direction. While hydraulic elevators are known for their smooth and quiet operation, they do come with their own set of common issues

One widespread issue with hydraulic elevators is oil leakage. In addition, concerns with the control system, such as damaged shutoffs or a malfunctioning pump, can trigger disruptions in the lift's activity.

Routine maintenance and prompt repairs are necessary to guarantee the smooth functioning of hydraulic lifts. By attending to these typical problems proactively, building owners can decrease downtime and make sure the security and efficiency of their upright transportation system.

Traction Lifts

When thinking about upright transport systems in buildings, an additional typical kind besides hydraulic elevators is the grip elevator. Grip elevators run utilizing a system of ropes and counterweights that move the lift automobile by gripping onto the hoist ropes. This system allows for smoother and much faster vertical transport compared to hydraulic systems.

Among the typical concerns dealt with by grip elevators is rope wear. The consistent movement of the ropes within the grip system can cause wear and tear over time, possibly triggering the elevator to breakdown or become harmful for use. Normal evaluations and upkeep of the ropes are essential to make sure the lift's proper performance and safety.

An additional issue that grip lifts may come across is connected to the control system. Problems with the control system can cause issues such as irregular movement, delays in reaction times, and even full shutdowns. Routine screening and upkeep of the control system are essential to stop such concerns and ensure the elevator's dependability.

Machine-Room-Less (MRL) Lifts

Among the crucial components of MRL elevators is the compact gearless grip maker that is installed within the hoistway. This machine successfully drives the lift auto without the need for bulky devices located in traditional traction lifts. Furthermore, MRL elevators commonly utilize a weight system to balance the vehicle, more boosting their power effectiveness.

Regardless of their benefits, MRL lifts might face difficulties connected to repair and maintenance due to the confined space for devices installment. Ease of access for servicing elements within the shaft can be restricted, calling for specialized training for specialists. Proper maintenance schedules and routine assessments are critical to ensure the continued smooth operation of MRL elevators.

Overloading and Weight Restriction Issues

Straining and weight restriction problems here are essential worries in elevator operations. Lift suppliers style lifts with specific weight capabilities to guarantee passenger safety and tools durability.

When elevators are strained, it places excessive strain on the motor, wires, and various other parts, potentially causing breakdowns or malfunctions. Security devices such as sensing units and overload sensors remain in place to protect against lifts from moving if they spot excess weight. In addition, surpassing weight restrictions can cause increased power intake and deterioration on the lift system.

To reduce overwhelming concerns, developing supervisors ought to plainly display weight limitations in continue reading this lifts and educate occupants on the relevance of adhering to these limitations - lift repair companies. Regular maintenance checks by certified specialists can additionally help make certain that elevators are running within safe weight specifications. By resolving overloading and weight limit problems proactively, structure owners can boost elevator safety and efficiency

Electrical System Failings

Exceeding weight limitations in lifts can not only lead to mechanical problems but additionally potentially add to electrical system failings within the lift facilities. Electrical system failings are an essential concern in elevator operation, as they can cause unforeseen closures, malfunctions, or also safety dangers.

Normal maintenance and examinations are vital to recognize and attend to possible electrical concerns promptly, making sure the efficient and secure operation of lift systems. By adhering to weight limitations and performing routine electrical system checks, structure owners can alleviate the risk of electrical failings in lifts.

Final Thought

Hydraulic lifts, commonly liked for low-rise buildings, use fluid pressure to regulate the motion of the lift automobile.When considering upright transport systems in buildings, an additional common type aside from hydraulic lifts learn this here now is the traction elevator. Grip elevators operate using a system of ropes and counterweights that relocate the elevator car by clutching onto the hoist ropes. Unlike conventional lifts that call for a separate equipment room to house the devices, MRL lifts integrate many of the components within the shaft, removing the need for a specialized machine room.In final thought, lifts face typical concerns such as hydraulic breakdowns, traction system failures, and electric system issues.

Report this page